When your garage floor has become an eyesore after years of heavy use, restoring it with a floor coating is the best solution.

When your garage floor has become an eyesore after years of heavy use, restoring it with a floor coating is the best solution.

Navigating the world of garage floor coatings can be confusing. There is a ton of information online about various types of floor coatings, including polyaspartic, epoxy, and polyurea coatings.

Which of these is the best garage floor coating?

To help you make sense of it all, we’ve narrowed our focus to do a comprehensive polyaspartic vs. epoxy floor coating comparison. We’re using Garage Living’s Floortex™ polyaspartic floor coating for our comparisons.

Floortex™ was specifically created for Garage Living and we use it exclusively because it’s the best polyaspartic floor coating on the market.

Polyaspartic vs. epoxy floor coatings: 17 features compared

Polyaspartic and epoxy coatings are the two most popular types of garage floor coatings. Both provide protection and decorative appeal for concrete garage floors and have additional similarities, as well as several major differences.

Epoxy is likely the type of floor coating you’re most familiar with. That’s the kind you see sold in do it yourself (DIY) kits in home improvement stores.

Polyaspartic and epoxy coatings are both resin-based flooring systems. Some garage floor companies use both materials in their application process. Other companies stick with just one type of coating material (Garage Living only uses Floortex™ polyaspartic floor coatings).

Even though it’s still considered a newer form of floor coating technology, polyaspartic arrived on the market in the 90s. It’s become widely used as a floor-resurfacing product everywhere from showrooms to warehouses to retail stores to home garages.

Let’s compare 17 features of Floortex™ polyaspartic coating and epoxy floor coatings that you will want to know more about.

1. Which coating offers better floor protection?

One of the main reasons anyone gets their garage floor coated is to protect the concrete. Garage floors have to endure a lot and eventually they’ll start showing their age. So which material comes out ahead in the polyaspartic vs. epoxy debate in terms of floor protection performance?

If you want the highest level of floor protection, Floortex™ polyaspartic coating is vastly superior to most epoxy coatings.

A time-lapse video of a damaged epoxy floor being removed and a polyaspartic floor coating being installed. Credit: Tom Moloughney, State of Charge. To see more of this project, watch the full video on YouTube.

The reason for this is mostly because of their different chemical makeups. Floortex™ is formulated with a more advanced technology than the epoxy coatings used in DIY kits and by budget floor installers. This makes them perform at a higher level when it comes to protecting garage floors from damage caused by:

- wear from vehicles and foot traffic

- water and humidity

- stains caused by vehicle fluids, household chemicals, and road salt

- chipping and cracking from concrete expansion and contraction

- abrasions and heavy impacts

- hot tire pickup (where hot tires can leave permanent floors marks)

In most of the above examples (except for hot tire pickup), epoxy coatings do offer protection, but only moderately compared to Floortex™.

Volume solids explained

Cheap epoxies have a low percentage of volume solids (also known as solids by volume). They’re heavily water or solvent-based and leave a much smaller amount of material on the concrete once the coating is dry.

Low-quality epoxy coatings can have 40% volume solids or lower, which only leaves a thin surface layer. Typically, these epoxies have to be applied in thicker amounts to achieve the same strength as a Floortex™ coating. Note that a higher solids percentage doesn’t necessarily mean you’re getting a thicker coating, as the thickness of any coating is ultimately at the discretion of the applicator.

High-quality epoxies and most polyaspartics used by pros have 85-100% volume solids. Floortex™ has 85% volume solids, which helps create an extremely durable protective surface on concrete floors.

2. Polyaspartic vs. epoxy coating appearance comparison

Almost any floor-resurfacing product improves a garage floor’s appearance. Even floor paint (the cheapest option) upgrades a garage’s aesthetic compared to having an unfinished concrete floor. Floor paint has virtually no protective functionality, however.

High-quality epoxy and polyaspartic coatings don’t merely upgrade a garage’s look – they transform it.

A professionally done floor really stands out because most garage floors look the same. They’re grey and drab, dirty, and damaged with cracks, pitting, and spalling (where the concrete crumbles or flakes away).

Applying an epoxy or polyaspartic coating with a high-gloss top coat makes a garage floor look clean, finished, and stylish. In garages with good lighting and lighter floor colors, the room will be brighter because light reflects better off the floor, too.

Do you want flakes with that?

You could get a floor coated with just a solid color, but why not live a little and spice things up by having decorative flakes added? Different-colored decorative flakes add texture and more visual interest to a floor’s appearance. This is one area where the highest-quality polyaspartic coatings like Floortex™ definitely come out ahead.

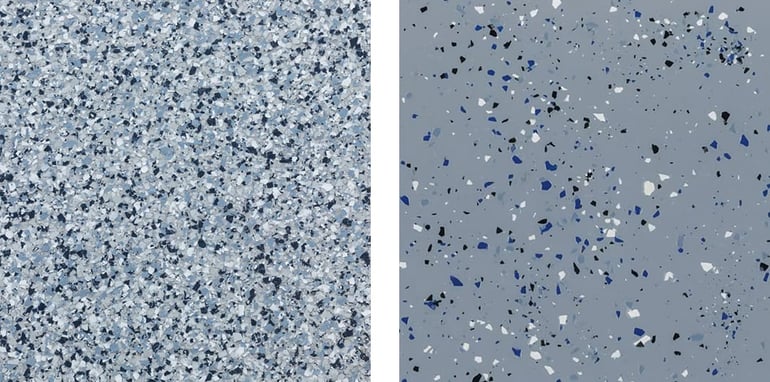

DIY epoxy coating products and budget flooring companies may offer flakes, but they typically use a less dense concentration of them on the floor. Compare the two close-up photos below of a Floortex™ polyaspartic coating on the left and a DIY epoxy coating on the right. We think you’ll agree that the Floortex™ results look much nicer.

The Floortex™ polyaspartic coating on the left is more stylish and visually appealing than the DIY epoxy coating on the right.

3. How much can you customize a floor’s look?

Choosing the right floor color for a garage remodel is essential because the floor is one of the room’s most prominent features. It needs to be in decorative harmony with the colors of your walls, ceiling, doors, and even your storage systems.

The variety of floor color options you can choose from naturally depends on the product manufacturer or floor company you decide on. You’ll find that your color options are fairly limited with a lot of garage flooring companies and even more so with DIY epoxies.

As with any home improvement project, having as many design options as possible is ideal. Garage Living specializes in creating stylish custom garage interiors and an attractive floor is a major component in bringing out a garage’s best look.

We understand that offering more design choices means having more garage owners who are completely satisfied when their remodel project is completed. Garage Living carries 18 dynamic Floortex™ floor coating colors so you can choose the colors and blend of decorative flakes that will best suit your space.

4. Polyaspartic vs. epoxy durability comparison

Consider the amount of wear that the average garage floor endures in its lifetime. There’s obviously a substantial amount of foot traffic, especially with more homeowners using the garage as the main entry point into their houses.

You’re in and out of the garage frequently when working in your yard. Perhaps your kids occasionally play in your garage or you spend time in there using a garage workshop. Storage boxes and bins will get dragged across the floor. In recent times, the garage even became a classroom for our kids.

And naturally, there’s the thing that causes more wear and tear on your garage floor than anything – vehicles coming and going and being parked. The average car weighs just under 3,000 pounds, so a garage floor needs to be extremely durable to handle all of these things.

If you’re assuming that since Floortex™ coatings provide better floor protection than cheap epoxies that they must also be more durable, you’d be correct. Floortex™ is approximately four times stronger than low-end epoxy floor coatings.

A Floortex™ polyaspartic floor coating provides excellent abrasion, impact, and wear resistance.

Why polyaspartic coatings last longer

Compared to epoxy, polyaspartic is far less affected by the stress put on concrete floors that comes with shifting temperatures. Unlike polyaspartic, epoxy doesn’t expand and contract well with temperature changes, which causes cracks and delamination (when a coating lifts, chips, and peels) to occur.

A high-quality, professionally applied polyaspartic floor coating like Floortex™ should last a decade or more. Cheap epoxy coatings, on the other hand, commonly need a full re-application after only a few years.

The typically thin layer that epoxies leave on a concrete surface also wears down faster from general wear and tear from vehicles and foot traffic compared to polyaspartics.

5. How much do the application processes differ?

Proper surface preparation for any type of floor coating application is essential to ensure the materials form a strong bond with the concrete. The entire floor surface must be clean and contaminant-free. Cracks and other surface imperfections need to be repaired.

Several factors have to be taken into account before polyaspartic and epoxy coatings touch a floor. The concrete’s moisture level and surface temperature and the garage’s air temperature and humidity level must be suitable. These factors determine how the coating materials should be mixed, how the floor will cure, and how the floor will look once it has dried.

Epoxy and polyaspartic coatings are typically 2-component systems. “Components” refers to the epoxy or polyaspartic plus the hardener (also known as a catalyst or curing agent) that are mixed together.

Getting the right mix is essential

It’s vital that the materials get precisely measured and properly mixed. Epoxies have a mix ratio in the range of 2:1 to 4:1.

The ratio refers to the amount of epoxy resin being used relative to the amount of hardener being used. For example, a 2:1 ratio means that two parts of the epoxy resin are mixed together with one part of the hardener. Polyaspartics have an easier-to-work-with 1:1 mix ratio, which decreases the chance of an installer making a bad mix.

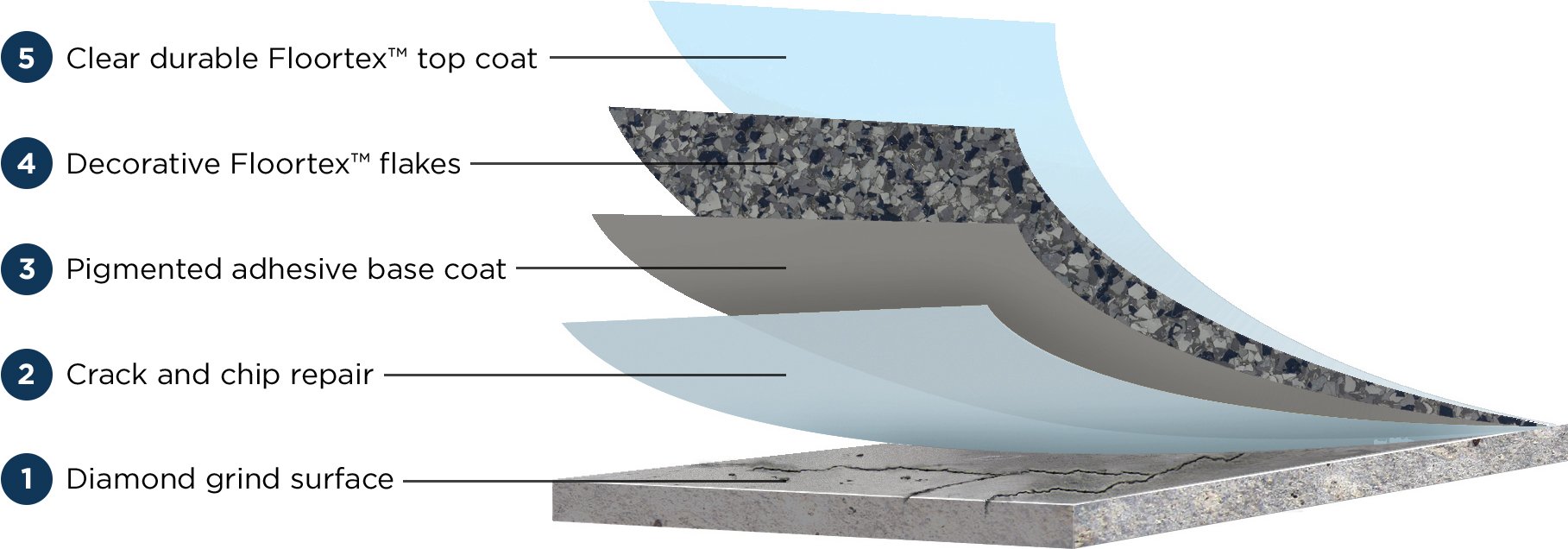

The 5-step Floortex™ floor coating application process

Garage Living has a 5-step floor coating application process (some companies that use polyaspartic coatings may have a slightly different process). Here is how a Floortex™ application is done:

- Our crews diamond grind the entire floor surface.

- Cracks, chips, and other surface imperfections are repaired and any dust and debris are removed.

- The pigmented polyaspartic base coat is applied (only one base coat is needed because it creates a greater film thickness than epoxies).

- Decorative flakes are broadcast on the floor and evenly spread. After the coating cures in 60 minutes, all excess flake material is scraped off.

- A clear top coat is applied with a squeegee and back-rolled to produce a thick, even layer.

A major difference between the two coatings is that Floortex™ coating applications can be completed much faster than epoxy applications. We’ll explain why next.

6. Curing and turnaround times comparison

Floortex™ projects have a significantly quicker turnaround time in comparison to epoxy-coated floor projects because polyaspartic cures much faster. Curing is the process where chemical reactions occur that make the coating materials harden and set.

Polyaspartic cure times range anywhere from 20 minutes to an hour, whereas epoxy takes up to 24 hours to cure. Applying multiple epoxy coats can put a garage out of commission for almost a week. Weather and environmental conditions may cause curing times to vary.

The rapid curing time of polyaspartic means a garage can accommodate light foot traffic around 12 hours after a project is completed (that’s how long it takes the top coat to cure). Vehicle traffic can resume anywhere from 24-96 hours after.

Yes, it is possible to have a major garage floor renovation started and finished in as little as one day!

7. How much does temperature affect the application process?

We’ve mentioned how a garage’s temperature has to be suitable for a coating application. Temperatures affect epoxy coatings to a much higher degree than polyaspartic coatings.

Epoxy coatings require a minimum temperature of 50-55° F (10-13° C) for an application to be done. They also can’t be used if temperatures exceed 85-90° F (29-32° C). Applying an epoxy coating in temperatures that aren’t in this narrow range will leave a floor with enough defects to necessitate a re-do of the entire project.

Polyaspartic coatings, however, are far less restricted by temperatures compared to epoxies. Because they’re not as sensitive to hot and cold temperatures, polyaspartic coatings can be applied virtually year-round anywhere in the U.S. and Canada.

Garage Living’s Floortex™ Extreme Cold Weather System allows Floortex™ to be used in temperatures as low as -40° F (-40° C). It also performs at a high level at temperatures up to 104° F (40° C).

Choosing a more versatile coating material like polyaspartic doesn’t limit a homeowner to getting their garage floor redone in the spring and summer, when contractors are at their busiest. In fact, the fall and winter are great times to get a floor coating and garage remodel, even if you live in a cold climate.

Unlike epoxy floor coatings, polyaspartic coatings can be applied year-round.

8. Can you DIY these garage floor coatings?

DIY epoxy floor coating kits are designed so that the average person can use them. That makes them inexpensive and lets anyone do their flooring project when it’s most convenient.

These two benefits of DIY epoxy floor coatings are offset with some major compromises, however. First of all, that cheap price means the product quality is going to be vastly inferior to what reputable professionals use. Second, there is no substitute for experience, especially when it comes to a challenging home improvement project like applying a floor coating.

We’ll say it again – proper floor prep is critically important with coating applications. This is where many DIY floor projects (and some done by inexperienced garage floor companies) fail.

Not only do the conditions need to be right, the floor properly prepared, and the materials mixed precisely, the coating application has to be done correctly and in a timely manner. There isn’t much room for error when you work with floor coatings. One mistake can leave you with a botched floor project, wasted time and money, and a lot of messy clean-up work.

Even if you don’t encounter any problems doing your own floor coating application, the results usually don’t look any better than “serviceable”. You’re not going to be blown away like you will if you hire a garage flooring expert.

Why you shouldn’t DIY polyaspartic coatings

Epoxy is used in DIY floor kits for a good reason – polyaspartic is harder to work with. It has a short pot life, which is the amount of time the mixed materials can be used before they harden.

The pot life of polyaspartic coatings is about 30 minutes, compared to 60 minutes for epoxies. Air temperature and how the materials are mixed factor into pot life duration.

You also need at least two people to do a polyaspartic application properly. And polyaspartic coatings cost more than epoxy coatings, so there’s a greater financial risk if the project is a failure.

Garage Living’s state-of-the-art equipment ensures every floor we coat with Floortex™ is properly prepared.

Here are some of the benefits of letting a professional handle a polyaspartic or epoxy floor coating application:

- they have the right equipment to achieve the best results (Garage Living’s professionally-trained installers use state-of-the-art equipment)

- you won’t have to deal with the frustration of learning on the job and seeing disappointing results

- you can leave the messy work to someone else

- enjoy the peace of mind of knowing the job was done right and won’t need to be fixed or redone for years

9. Floor penetration and bonding comparison

High-performance floor protection from a coating only happens if it forms a strong bond with a concrete floor. This is achieved when a coating penetrates deeply enough into the concrete.

Despite its hardness, concrete is actually quite porous. Polyaspartics are engineered to take advantage of concrete’s porosity so they soak into it and cure within the top-most layers, ensuring a stronger adhesive bond is formed.

Most epoxy coatings don’t penetrate concrete and cure on the top of the surface, which only creates a topical bond. Epoxy’s less effective bonding capabilities are one reason their coatings are less resilient than polyaspartics.

Be leery of misleading online information that tells you epoxies adhere to concrete better than polyaspartics do. That’s only true if a substrate (the subfloor area concrete gets poured onto) is properly prepped with a process known as shotblasting. Not only is this process prohibitively expensive, there are also few residential garage floor coating companies that actually do it.

10. How well do these coatings seal garage floors?

Garage floors encounter water regularly, whether it’s from rain, ice, and snow that gets brought in on vehicles or other methods like using a hose to clean a floor.

Because concrete is porous, all that water takes a toll on the floor over time. Moisture that gets absorbed into the concrete will eventually cause cracks and other types of damage.

In the polyaspartic vs. epoxy comparison, which floor coating does a better job at sealing the floor and preventing damage from water?

Epoxy coatings offer some protection, but they have a lower degree of water resistance compared to polyaspartics. Floortex™ creates a 100% seamless and non-porous water-resistant floor seal. Any water that touches a garage floor stays on the top surface where it can evaporate or be squeegeed or mopped up, not absorbed into the concrete.

11. Polyaspartic vs. epoxy: which one is more flexible?

Along with how porous it is, you’ll probably be surprised to learn that concrete is quite flexible. So why is the flexibility of the floor something you should concern yourself with when you’re choosing a floor coating?

A concrete garage floor needs elastic properties so it can handle the expansion and contraction that occurs with thermal fluctuations.

Polyaspartic has superior elasticity compared to epoxy, which is more brittle. How much better? A lot. High-quality polyaspartic coatings are 98-100% more flexible than epoxy coatings.

12. Ease of maintenance comparison

Garages have a fair amount of dust that comes from many sources. Pet dander, clothing fibers, dead skin cells (yuck), dirt, pollen, dead insects, and particles from home building materials are just some of the things that generate household dust.

Unsealed concrete floors contribute to garage dust issues by slowly wearing down and leaving a fine, powdery residue.

An epoxy or polyaspartic floor coating significantly reduces the amount of dust that unfinished garage floors create. Here are four cleanliness-related benefits you’ll enjoy simply by getting a quality floor coating:

- your garage will stay cleaner and need less cleaning work

- sweeping, mopping, and using a squeegee on a smooth, even floor makes cleaning easier

- decorative flakes help obscure dirt and dust

- the garage’s air quality improves

13. Which garage floor coating provides better traction?

The next category in our polyaspartic vs. epoxy comparison is floor traction. It’s a reasonable concern to wonder whether or not an epoxy or polyaspartic coating makes a floor too slippery when it gets wet and the temperature drops below freezing.

If the floor doesn’t have decorative flakes, a traction agent like silica sand can be added to the top coat to improve slip resistance.

For floors with decorative flakes, the textured finish they provide improves foot traction and should suffice for most people’s needs.

If desired, both decorative flakes and a grit additive can be added to a top coat mix for garage floors that deal with a higher-than-average amount of water.

14. UV stability and color stability comparison

Anyone with an attractive new floor coating wants to keep it looking new for as long as possible. Without the right kind of floor coating, however, prolonged exposure to UV rays will eventually cause the coating to discolor and yellow. If it has a shiny top coat, that shine will fade eventually, too.

A polyaspartic floor’s top coat won’t discolor or lose it’s high-gloss appearance with exposure to sunlight like an epoxy-coated floor will.

Epoxy coatings aren’t protected from UV rays, unlike polyaspartics. That’s a problem unless no sunlight ever touches your garage floor, which isn’t the case with most homes. Some epoxies have UV inhibitors that will reduce the damage done by UV exposure, but they’re still not as protective as polyaspartic coatings.

Floortex™ provides the highest-caliber UV stability to prevent a floor’s colors and top coat shine from fading.

15. How environmentally-friendly is each floor coating?

Many of us are more conscious about the materials we use to build and renovate our homes. Lead paint and asbestos were considered safe to use a long time ago. Nowadays? Not so much.

Floor coatings are obviously made with a bunch of chemicals, so you may want to know how safe and environmentally-friendly the coating you buy is.

Quality polyaspartic and epoxy floor coatings are considered environmentally-friendly. They have low to ultra-low levels of VOCs (volatile organic compounds), which are chemicals found in many products that slowly off-gas. Quality coating products shouldn’t leave anything more than a mild, non-toxic odor that will disappear shortly after an application is completed.

“Quality” is the operative word here. Cheap polyaspartic and epoxy floor coatings will probably have higher levels of VOCs and an odor that lingers longer after a flooring project is done.

16. Can you use these floor coatings for vertical applications?

Polyaspartic floor coatings may have been designed for use on garage floors, but they’re also great for vertical applications. Why would you want to use a floor coating on a wall or other vertical surface, you ask?

Let’s start with the fact that applying a coating to a garage’s lower wall area that matches the floor coating adds decorative appeal. It gives garages a consistent, seamless, and unique look. That consistent look can be extended to the steps by a garage entry door and sidewalks around a garage, which can be coated as well.

Baseboard coating applications also fully seal the area between the garage floor and walls. Covering up any gaps with a floor coating:

- prevents water from getting inside the walls

- keeps pests out

- eliminates drafts for better garage energy-efficiency

A vertical baseboard coating provides a beautiful, consistent, and seamless look.

Floortex™ and other high-quality polyaspartic coatings are better suited for vertical applications, partly because of their fast cure time. Epoxy isn’t weighted properly for vertical applications and its very slow cure time results in some of the epoxy running down the wall before it can harden.

Most budget garage floor companies that use epoxy coatings don’t offer vertical surface coating or only coat vertical surfaces in a solid color without flakes.

17. What is the most affordable garage floor coating?

There’s no denying that a polyaspartic vs. epoxy coating price comparison comes out in favor of epoxies. Epoxy coating materials simply cost less to manufacture than the materials polyaspartic coatings are made with.

But if you’ve read this far and taken the time to research the merits of each type of coating, you can see why a professional polyaspartic floor coating application is well worth the extra expense.

Compared to any epoxy floor coating, a high-quality polyaspartic floor coating like Floortex™ looks and performs better. The expertise of Garage Living’s installation pros and the specialized equipment we use ensure the quality and durability of our floor coating applications are second to none.

Floortex™ vs. epoxy floor coatings – the best choice is clear

We hope the differences between polyaspartic and epoxy floor coatings are much clearer to you now. We think you’ll agree that the best coating choice for your garage floors is Floortex™.

For more information, view our garage floor coating comparison chart at the bottom of this page.

Let’s start laying the groundwork for your custom garage remodel. Schedule your free design consultation with Garage Living today.